Deacon Engineers have provided specialist services to multiple mining companies ranging from certification of lifting equipment, to designing new handling systems and upgrading equipment for increased capacity.

We provide asset support services to operators to improve capacity and manage failing equipment by using our state of the art data acquisition and analysis tools. Whether we strain gauge equipment or undertake detailed fatigue and structural analysis of plant, we provide clients with effective solutions.

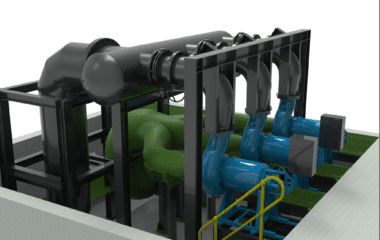

Water and Waste Water Engineering includes many aspects of the water-cycle, from sourcing drinking water to treating and discharging wastewater from urban and industrial facilities.

Deacon Engineers and environmental organisations can work together to manage the use of water resources, while maintaining appropriate levels of environmental protection.

At Deacon Engineers, we provide design solutions designed to assist operators and maintainers of water and waste water facilities maintain and improve their systems performance. Whether it be design improvements to small auxiliary plant or major redesigns of process plant we can provide the expertise and advanced analysis tools to deliver solutions to your problem.

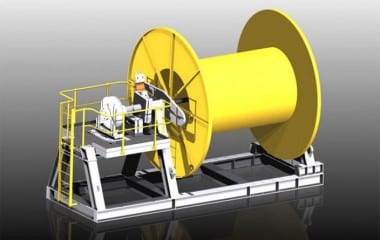

From cranes to handling systems to support structures, Deacon Engineers provide complete solutions to clients in the Manufacturing, Marine and Industrial sectors

We provide support from design and verification of classified plant, through supporting manufacturing activities to installation and commissioning of equipment.

We provide manufacturers with local technical support of their product as well as provide engineering design and development of new products and services.

For a sustainable future, our attitudes towards waste must change. We have been privileged to provide engineering services to assist forward looking companies that see Municipal Solid Waste as a resource rather than rubbish.

Our involvement includes design of process equipment, equipment assessment and equipment modification. In particular, Deacon Engineers have developed specialist design methodologies that consider multi axial fatigue in large welded rotary composters and digesters. These design methodologies provide plant operators and owners with designs that are economical. They outlast equipment designed only considering uniaxial fatigue.

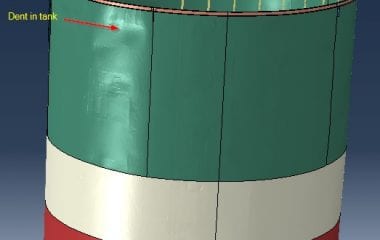

Deacon Engineers offers a range of services to plant owners, and operators of mineral processing equipment.

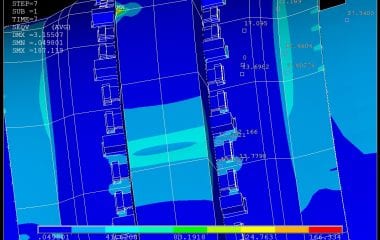

As well as general mechanical, structural and electrical design work Deacon Engineers provide specialist analyst services considering multi axial fatigue of rotating equipment. Complex designs can be completed in short time frames using powerful specialist software.

For brownfield sites Deacon Engineers can survey and redesign plant to suit changes to your requirements. Be it for improved safety, production or efficiency. Deacon Engineers also provide stain gauging services coupled with powerful finite element analysis for plant troubleshooting, life prediction and improvement.

Whether it be minor adjustments to improve an access way or major redesigns of process plant we can provide the expertise. Our advanced analysis tools will deliver solutions to your problem.