3D Laser scanning, how it works.

3D Laser scanning has changed the way we take site measurements. By using our own high-precision 3D Laser scanner, we can accurately measure up to 80m.

Our scanner captures up to a million points per second. Each radial scan is completed in minutes. Because our 3D laser scanner uses a Class 1 laser it is safe under all conditions of normal use. Therefore the maximum permissible exposure (MPE) cannot be exceeded when viewing a laser with the naked eye.

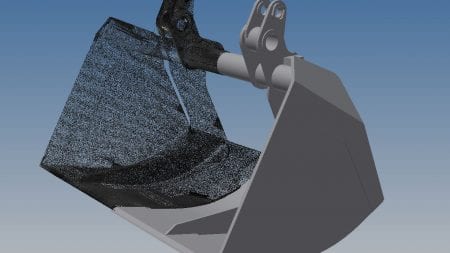

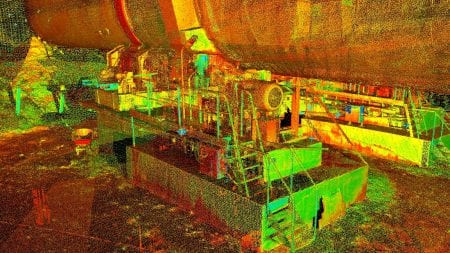

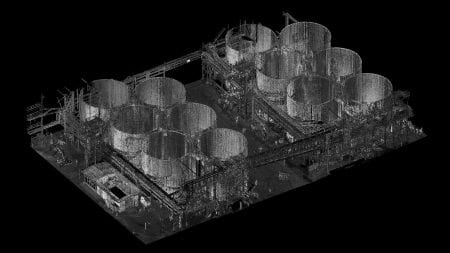

Our 3D Laser scanner is moved to a number of vantage points around a site or piece of plant to capture the data required. We process this data by registering all scans together to form a single point cloud. From the point cloud, we can add geometry, surfaces and take measurements that can be used by third parties. In addition, point cloud data can be used for the production of as-built drawings. We have also used laser scan data for adding new features that are required to interface with the existing structure.

Why use 3D Laser Scanning?

There are a number of real benefits in laser scanning your next project. Firstly, point cloud data has great dimensional accuracy when compared with more manual methods. Secondly, the scale of data collection over a such short period is astonishing. As a result, the time and cost savings, not to mention inherent safety benefits can make 3D laser scanning the preferred option for data acquisition. Most 3D laser scanning can be completed on the ground or on platforms. So in addition to the scale and accuracy of data collected, it is a much safer method of measuring.

The value of point clouds is accentuated in complex and detailed environments. For instance, a tape measure may work in the most basic of environments, but the data is only as accurate and complete as the person on site is able to capture. It is not unheard of to hear from engineers who measure existing projects and end up returning to the site multiple times to re-check. However, the result is that the final cost for all their re-checking is usually close to if not over, the cost of an initial laser scan.

So what could you use 3D Laser scanning for?

- Integrity assessments of equipment, tanks, and structures

- Reverse engineering

- 3D Modelling of piping installations

- 3D Modelling of structural items

- Calculate volumes of tanks and vessels

- Collision detection and avoidance

- Wear monitoring

- Alignment surveys

We have carried out many laser scanning projects within Australia. Hit the button below to view our Capability Statement for some real life example applications.